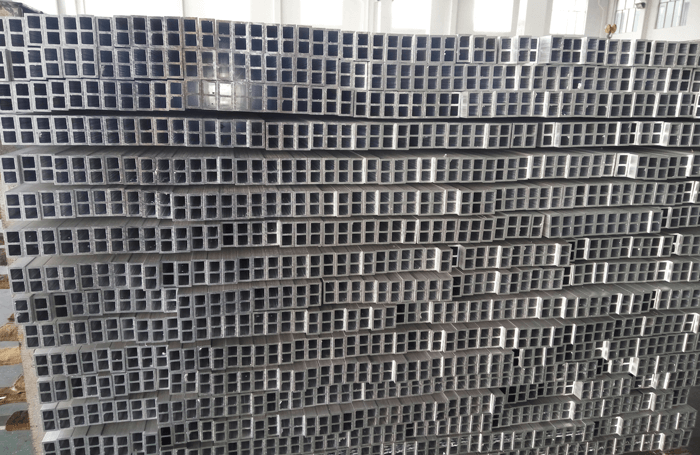

With the emergence of industrial automation, the industry's requirements for the accuracy of production materials are getting higher and higher. The birth of the aluminum profile lean tube simplifies the production process and materials at the same time, which meets the strict requirements of modern industry for lean production. The production and processing of pipes are carefully controlled, but various problems are inevitable. Today, let's talk about how the concave and convex corrugations on the surface of the pipe are generated, and how to avoid this topic.

The aluminum profile lean tube is an aluminum material produced by heating, melting and extruding aluminum bars. The cross-section is a cross-shaped vertical two-way positioning structure. 2.0mm range. During extrusion, an aluminum extrusion die needs to be used, and it is carried out in accordance with the specified production operation process. During the extrusion process, uneven corrugations appear on the surface of the lean pipe profile due to the following problems:

1. The size of the support pad is too small

When the aluminum extrusion die is released at high temperature, it should be placed on the support pad within a specified time, and a support pad of suitable size should be prepared according to the cross-sectional shape of the die. If the size of the support pad is too small, it will cause certain damage to the lower die. The elastic pressure makes the size of the mold unstable, and the surface of the extruded aluminum lean pipe produces uneven ripples.

2. There are debris on the working belt of the extrusion die

If the surface of the working belt is not clean, oil stains or debris blocks, the surface of the produced aluminum profile lean pipe will appear pits and pits, resulting in unqualified shape, size and appearance quality of the product.

3. The upper and lower dies of the aluminum extrusion die are not parallel

The design or use of the mold is improper, the upper and lower molds are not parallel, and the shape of the bell mouth appears, so that the surface of the extruded aluminum lean tube material will be uneven after cooling and forming.

4. Uneven extrusion speed

The initial extrusion speed was not paid attention to when the new mold was used, the head and tail of each aluminum rod were not properly reserved, and the surface of the extruded product was uneven.

5. The size of the empty knife of the mold is too small

If the size of the empty knife is too small, the metal flow will not be smooth, the speed will be uneven, and the fast and slow flow rate will cause the mold to be scratched, which will cause uneven appearance defects on the surface of the extruded aluminum lean tube.

Elimination method

1. Make preparations before the mold is released, select a special support pad with double holes and a large cantilever of the appropriate size, and heat the support pad to 350-450 ° C to prevent the mold from taking a long time to find the support pad after it is released. Stuffy car phenomenon occurs, to ensure the dimensional stability of the aluminum lean tube, and to reduce the generation of surface bumps and ripples.

2. Keep the hygienic condition on the working belt up to the standard, free of oil and other sundries, remove all obstacles, ensure the smooth circulation of aluminum alloy, and make the surface of the produced aluminum profile lean pipe smooth.

3. The mold design should be reasonable, and the size requirements should be strict. Pay attention to the daily maintenance of the mold during use. If there is any phenomenon such as non-parallel, repair the mold in time, and replace the mold if necessary.

4. When using a new mold, pay attention to reducing the extrusion speed of the first aluminum rod, or pause for a period of time to flatten the metal on the working belt, and reserve at least 1mm at the tail of the material when cutting. The excess pressure can reduce the generation of ripples.

5. The size of the empty knife of the mold should be reasonably selected. If the mold is scratched because the empty knife is too small, lubricating oil can be applied to the side of the working belt that is too small to make the metal flow smoothly, keep the speed uniform, and squeeze The probability of unevenness on the surface of the outgoing aluminum lean tube is greatly reduced.

In short, the extrusion process of aluminum profiles is a very complicated process. It is necessary to operate in strict accordance with the extrusion process flow, pay attention to the daily maintenance of the mold, and control various extrusion defects from the source to ensure the appearance of the aluminum profile lean tube. The size is qualified, making it more in line with the requirements of lean production, and achieving low-cost use in light industrial environments.