APPLYING ASTMB210, DIN EN 754 ON COLD DRAWN SPECIFICATION ON BEST TOLERANCE +-0.02MM

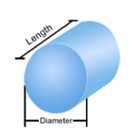

1.Size Range

|

Extruded Aluminum |

Al-Alloy |

Temper |

Stretching Test |

Hardness HB |

Temper |

We Are Able To Produce Sizes Of |

||||||

|

Tensile Strength Rm/Mpa |

Yield Strength Rp0.2/Mpa |

Elongation A% |

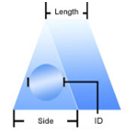

OD |

ID |

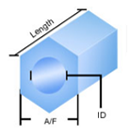

Diagonal |

A/F |

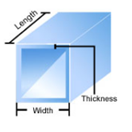

Length |

|||||

|

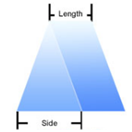

Round bar Square bar Triangle Bar Hex bar Round tube Square tube Triangle tube Hex tube Square tube II Slot Channel Angle |

7003 |

T5 |

>285 |

>245 |

>10 |

110 |

O T73 T6/T651 T8 F |

3mm~ 130mm |

3mm~ 100mm |

3mm~ 130mm |

5mm~ 112mm |

1000mm~ 6000mm |

|

7005 |

T6 |

>400 |

>350 |

>12 |

130 |

|||||||

|

7022 |

T6 |

>460 |

>380 |

>8 |

130 |

|||||||

|

7050 |

T73 |

>490 |

>430 |

>9 |

140 |

|||||||

|

7075 |

T6 |

>540 |

>480 |

>7 |

150 |

|||||||

|

7055 |

T6 |

>650 |

>600 |

>8 |

170 |

|||||||

2.Temper

|

Annealing |

TO |

|||||||

|

Hot work |

T1 |

H111 |

H112 |

|

||||

|

Cold work |

H12 |

H14 |

H16 |

H18 |

H32 |

H34 |

H116 |

H321 |

|

Heat treatment |

T3 |

T4 |

T5 |

T6 |

T8 |

|

|

|

|

Over aging treatment |

T73 |

T74 |

T76 |

T79 |

|

|

|

|

|

Stress relieved |

T351 |

T451 |

T651 |

T7351 |

T7451 |

T7651 |

T7951 |

T851 |

3.Inspection Samples

|

Mechanical Properties |

|||||||

|

Temper |

Tensile Strength Rm/Mpa |

Yield strength Rp0.2/Mpa |

Elongationg Percentage A% |

Hardness HB |

|||

|

7005 T6 |

Standard |

≥350 |

Standard |

≥290 |

Standard |

≥10 |

- |

|

Actual |

390~400 |

Actual |

340~360 |

Actual |

14~16 |

115~125 |

|

4.Application

|

Material Type |

Material shapes |

Application |

Material & Temper |

|

Seamless drawn tube Seamless extruded tube |

Seamless round tube |

Medical wheel chair tube |

7005 - T53 |

5.Characteristic

-Alloy Series: 7000 Series(Al-Zn-Mg-Cu Alloy)

This alloy has currently the highest strength, can replace carbon steel, widely used in military, aerospace. Due to the oxidation of the surface having a breakthrough in recent years, it has been used by civilian.

-Typical Alloy:7A04 7050 7055 7075

-Temper:T3, T351,T4,T451,T6,T651,T6511,T7351

-Features :Mechanical properties are the highest in aluminum, corrosion resistance is relatively poor, can be improved through the process.

-Applications:Mold manufacturing Aircraft structural parts with plate Free Forging and Die Forging car parts Sports Equipment.

6.Cases

|

|

Automotive Aluminum |

|

Electronic Product |

|

|

|

||

|

|

Product Advantage |

|

|

|

|

|

|

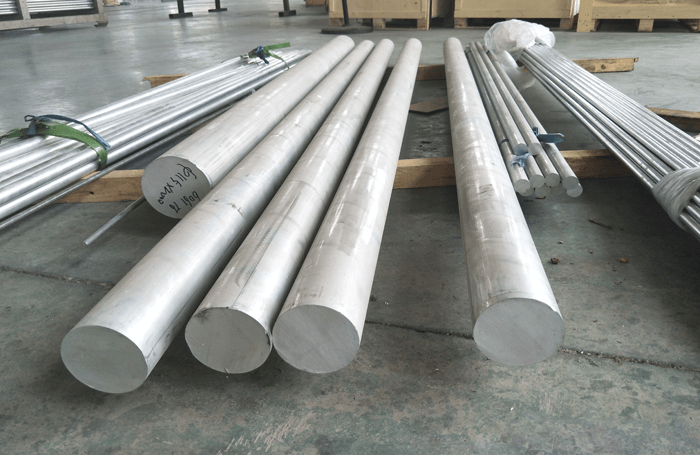

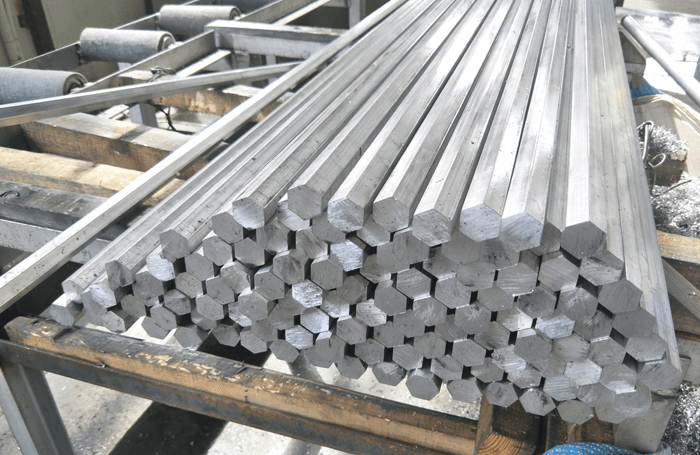

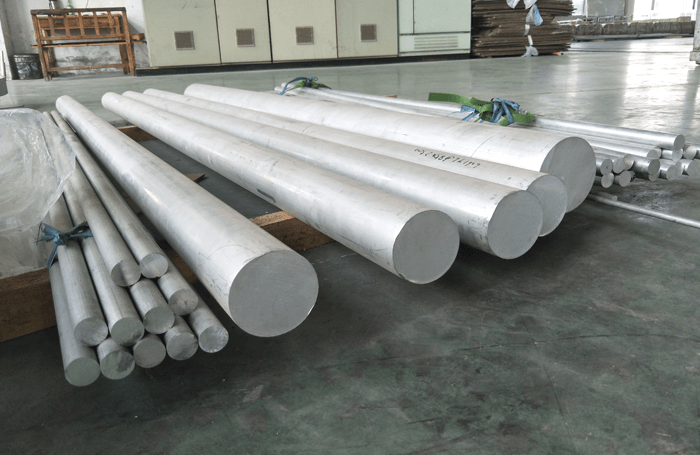

Aluminum Alloy Bar |

|

|

|

|

|

|

7.Packages

|

Package |

|||

|

|

|

|

|

|

Aluminum Plate(Kraft Paper) |

Aluminum Seamless Pipe |

Aluminum Plate(PVC Flim) |

Aluminum Bar |

|

|

Category |

|||

|

Extruded

Aluminum |

||||

|

ROUND

BAR |

SQUARE

BAR |

TRIANGLE

BAR |

HEX

BAR |

|

|

ROUND

TUBE |

SQUARE

TUBE |

TRIANGLE

TUBE |

HEX

TUBE |

|

|

SQUARE

TUBE Ⅱ |

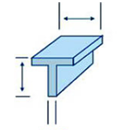

SLOT |

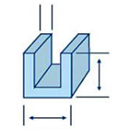

CHANNEL |

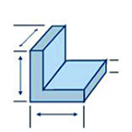

ANGLE |

|